Truck maintenance, a vital aspect of fleet management, ensures optimal performance and safety. Get ready to dive into the world of truck upkeep with essential tips and tricks to keep your vehicles in top shape.

From checking fluids to troubleshooting common issues, this guide will equip you with the knowledge needed to tackle any maintenance challenge head-on.

Importance of Truck Maintenance

Regular truck maintenance is essential for effective fleet management. By ensuring that trucks are well-maintained, businesses can prevent costly breakdowns, reduce downtime, and extend the lifespan of their vehicles. Neglecting maintenance can have a significant impact on both truck performance and safety.

Impact of Poor Maintenance, Truck maintenance

Poor maintenance can lead to a variety of issues that can affect truck performance and safety. For example, failing to replace worn-out brake pads can result in decreased braking efficiency, increasing the risk of accidents. Ignoring regular oil changes can lead to engine damage and reduced fuel efficiency, costing the company more in the long run.

- Failure to check tire pressure regularly can result in blowouts, putting the driver and other road users at risk.

- Ignoring routine inspections of the cooling system can lead to overheating and engine failure.

- Not addressing small issues promptly can escalate into major repairs, causing more downtime and higher repair costs.

Key Components of Truck Maintenance

Regular maintenance of trucks is crucial to ensure optimal performance, longevity, and safety on the road. By inspecting and servicing key components, you can prevent breakdowns and costly repairs down the line.

Fluids

Regularly checking and changing fluids such as oil, coolant, transmission fluid, and brake fluid is essential to keep the engine running smoothly. Low or dirty fluids can cause engine damage and reduce efficiency.

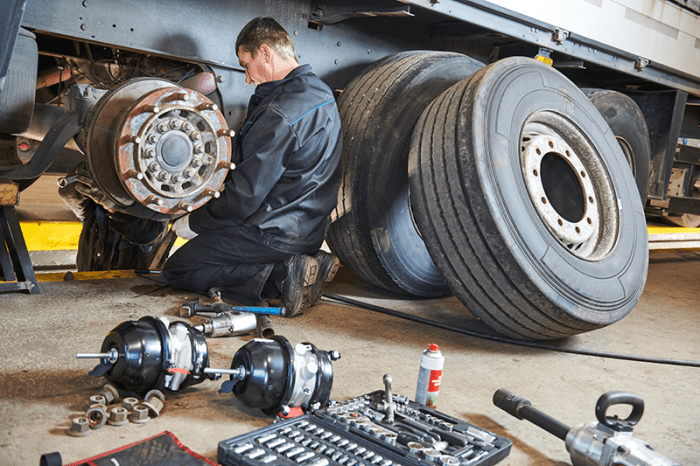

Brakes

Properly functioning brakes are vital for the safety of the driver, passengers, and other vehicles on the road. Regular inspections and adjustments can prevent accidents and ensure quick response times.

Tires

Maintaining proper tire pressure, tread depth, and alignment can improve fuel efficiency, traction, and overall vehicle handling. Inspecting tires for wear and tear can also prevent blowouts and accidents.

Electrical Systems

Checking the battery, lights, wiring, and other electrical components is crucial for ensuring proper functionality and avoiding unexpected breakdowns. Faulty electrical systems can lead to issues with starting the vehicle or operating essential functions.

Preventive maintenance of these key components can help identify potential problems early on and address them before they escalate into major issues. By staying proactive with regular inspections and servicing, truck owners can save time, money, and headaches in the long run.

Best Practices for Truck Maintenance

Maintaining your truck is crucial for ensuring its longevity and optimal performance. Here are some best practices to follow:

Creating a Truck Maintenance Schedule

Creating a regular maintenance schedule is essential for keeping your truck in top condition. Follow these steps to create an effective maintenance schedule:

- Start by referring to your truck’s manual to determine the manufacturer’s recommended maintenance intervals for various components.

- Consider your truck’s usage and operating conditions when setting maintenance intervals. For example, trucks used for towing or off-roading may require more frequent maintenance.

- Use a calendar or maintenance tracking software to schedule routine maintenance tasks, such as oil changes, tire rotations, and brake inspections.

- Stick to your schedule and make adjustments as needed based on your truck’s performance and any unusual symptoms.

Benefits of Using Technology for Tracking Maintenance Tasks

Utilizing technology for tracking maintenance tasks offers several benefits, including:

- Efficient organization of maintenance schedules and reminders for upcoming tasks.

- Access to historical maintenance records for tracking trends and identifying potential issues early.

- Integration with diagnostic tools for monitoring real-time performance data and detecting problems promptly.

- Enhanced communication with mechanics or service centers for streamlined coordination of maintenance services.

Finding a Reliable Mechanic or Service Center for Maintenance

Finding a trustworthy mechanic or service center is essential for quality maintenance services. Consider the following tips:

- Ask for recommendations from fellow truck owners or online forums to find reputable mechanics with experience in servicing trucks.

- Research the reputation of different service centers by checking online reviews, ratings, and customer feedback.

- Inquire about the certifications and qualifications of mechanics at the service center to ensure they have the expertise to work on your truck.

- Visit the service center in person to assess the cleanliness of the facility, the level of organization, and the professionalism of the staff.

Common Truck Maintenance Challenges

When it comes to maintaining trucks, there are several common challenges that truck owners face. From basic maintenance issues on the road to scheduling maintenance for a fleet of trucks, these challenges can be daunting. Let’s dive into some strategies for troubleshooting and overcoming these obstacles.

Basic Maintenance Problems on the Road

One of the most common challenges truck owners face is dealing with basic maintenance problems while on the road. From flat tires to engine issues, having the necessary tools and knowledge to troubleshoot these problems can be crucial.

- Always carry a basic toolkit with essentials like a tire pressure gauge, lug wrench, and jumper cables.

- Regularly check fluid levels and tire pressure before hitting the road to prevent common issues.

- Be familiar with your truck’s manual to quickly address warning lights or unusual sounds.

Overcoming Challenges in Scheduling Maintenance

Scheduling maintenance for a fleet of trucks can be a logistical nightmare, especially when considering downtime and operational costs. Finding efficient ways to overcome these challenges can help keep your trucks running smoothly.

- Implement a preventive maintenance schedule to address minor issues before they turn into major problems.

- Utilize fleet management software to track maintenance tasks and schedule appointments efficiently.

- Work closely with maintenance providers to establish a priority system based on urgency and importance.